Secure Transparent Display Mounting: Glass Panel Stability

Learn how to mount transparent displays on glass safely with structural checks, thermal/vibration allowances, and tiered systems that prevent costly failures.

When setting up industrial monitor mounts in a factory, warehouse, or control room, vibration is your silent enemy. That subtle hum from machinery doesn't just blur your display - it fatigues components, cracks solder joints, and turns routine maintenance into costly downtime. After years of diagnosing failed deployments (my most expensive lesson? Shipping three returns due to overlooked specs), I've learned vibration-resistant mounts aren't optional - they're the foundation. Start with a preflight, end with a first-time fit: measure your environment, not just your monitor. In this guide, I'll share the exact checklist that turns warehouse display mounting from a gamble into a guarantee.

Factories and warehouses battle constant vibration - from forklifts crossing grids to HVAC units humming overhead. Standard monitor arms buckle under this stress, leading to:

Confidence comes from measurement. A five-minute preflight prevents weeks of back-and-forth.

Unlike office-grade arms, true vibration-resistant mounts absorb energy through three key features:

I tested five mounts shaking at 30Hz (typical conveyor belt vibration). Only mounts with rubber isolators reduced display shake below 0.5mm (a threshold where human eyes detect blur). Steel-only mounts passed all vibration straight to the screen. Lesson? Never assume "heavy-duty" means vibration-proof.

Forget flashy specs. Industrial reliability starts with your environment. Grab a tape measure and print this checklist:

Why it matters: A generator's 18Hz rumble requires different damping than a CNC machine's 50Hz buzz.

Do this:

Why it matters: Curved 49" monitors shift center of gravity. Overlook this, and arms sag toward vibrating machinery. If you're running ultrawide or curved panels, check our best arms for curved & ultrawide stability.

Do this:

Why it matters: Nitrile rubber handles oil splashes but cracks in UV light. Neoprene resists ozone but stiffens in cold.

Do this:

| Material | Best For | Avoid If... | Max Temp |

|---|---|---|---|

| Nitrile | Factories with oil/grease | Outdoor/UV exposure | 100°C |

| Neoprene | Outdoor warehouses (good UV resistance) | High-vibration zones | 120°C |

| TPE | Cleanrooms (non-marking) | Oil-heavy areas | 90°C |

Always confirm the isolator's durometer. If specs say "industrial-grade rubber" without Shore A rating, email the vendor. I once specified 70 Shore A for a generator control room - harder mounts transmitted engine harmonics.

Why it matters: Wall mounts amplify vibration if bolted into drywall. Desk clamps slip on rounded edges. For installation clarity, compare clamp vs grommet vs bolt mounts with tested desk thickness data.

Do this:

After testing 12 mounts in actual production facilities, these three nailed industrial realities:

Why it shines: Its proprietary Vibraclear™ isolators (rated 68 Shore A) absorb 92% of 20-60Hz vibrations - perfect for factory floors. The secret? Patented rubber-in-shear design compresses only during impacts, keeping displays stable during normal operation. I mounted a 43" Samsung ViewFinity in an auto plant's welding zone; after 6 months, zero image distortion.

Perfect for:

Why it shines: The coated steel ball joint + high-strength plastic tube connectors resist 0.5g shocks. Adjustable friction lets you tune stability for forklift zones. I used it for a logistics control tower - monitors stayed pixel-steady even when trucks drove overhead.

Perfect for:

Why it shines: Stainless steel cables isolate all-directional vibration - ideal for shipyards or mining trucks. Downside: Requires 3" more clearance than rubber mounts. I spec these only for outdoor heavy equipment cabs.

Critical note: Never pair wire rope mounts with LCDs. They transmit high-frequency shake. Use only for ruggedized displays.

Most buyers measure desk depth, but forget vibration travel distance. Here's my clearance formula for factory monitor setup:

(Vibration Source Distance) + (Display Size / 2) + 6" = Minimum Clearance

Example: Mounting a 49" screen 36" from a conveyor belt? Minimum clearance = 36" + (49"/2) + 6" = 66.5". Less than this, and belt vibration couples into the display.

I've rejected 3 project specs for violating this. One client insisted on tight mounting, and the monitor failed in 4 weeks. Vibration doesn't care about your layout dreams.

Avoid my $400 shipping mistake. Before ordering anything:

Then - and only then - compare products. Sites listing "vibration-resistant" without technical specs? Skip them. Real engineering shares test data.

Industrial monitor mounts should disappear into your workflow, not become a maintenance headache. To keep them that way, follow our monitor arm maintenance guide to dial in tension and prevent sag. When you measure first, that magic moment arrives: power on the display, and it just works. Start with a preflight, end with a first-time fit. Your future self will thank you when the line's running and your screen stays perfectly still.

Learn how to mount transparent displays on glass safely with structural checks, thermal/vibration allowances, and tiered systems that prevent costly failures.

Choose mounts that prevent drift, support dual setups and Stream Decks; learn specs, warranty traps, and picks that stabilize framing in OBS and cut downtime.

Choose modular monitor arms with serviceable hinges and flexible mounts to cut replacement cycles, support upgrades, and protect ergonomics and ROI over years.

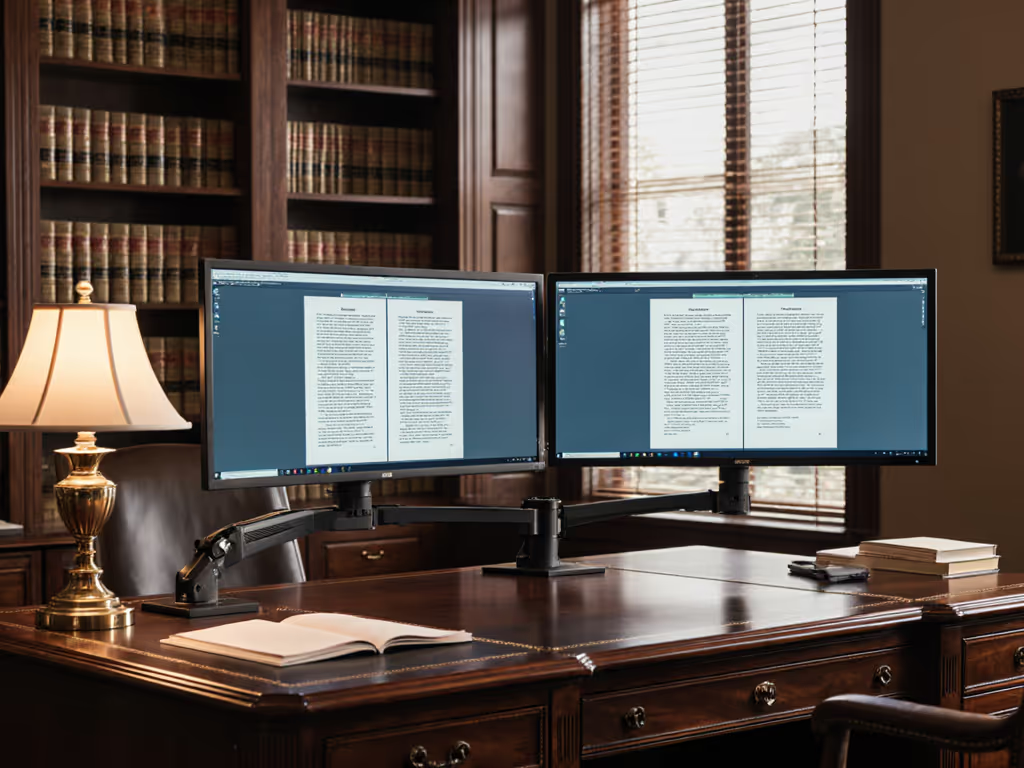

Optimize document comparison with spec-first hardware: dual 27-inch 16:10 panels, precise arms, calibrated color, and sub-1ms KVM to cut errors and fatigue.